Click on the categories to display the questions. Click on the questions to display answer. (Click to display all close all)

Atmosphere control  Delivery and Shipping

Delivery and Shipping  Electrode contact assemblies, springs, gas tubes, etc.

Electrode contact assemblies, springs, gas tubes, etc.  Furnaces

Furnaces  ProboStat - General

ProboStat - General  ProboStat - Maintenance

ProboStat - Maintenance  ProGasMix

ProGasMix  Samples

Samples  Sealing

Sealing  Support

Support  The company

The company  Thermocouples and temperature control

Thermocouples and temperature control  Troubleshooting - ProboStat

Troubleshooting - ProboStat  Visiting Oslo

Visiting Oslo

|

|

I have problem with temperature

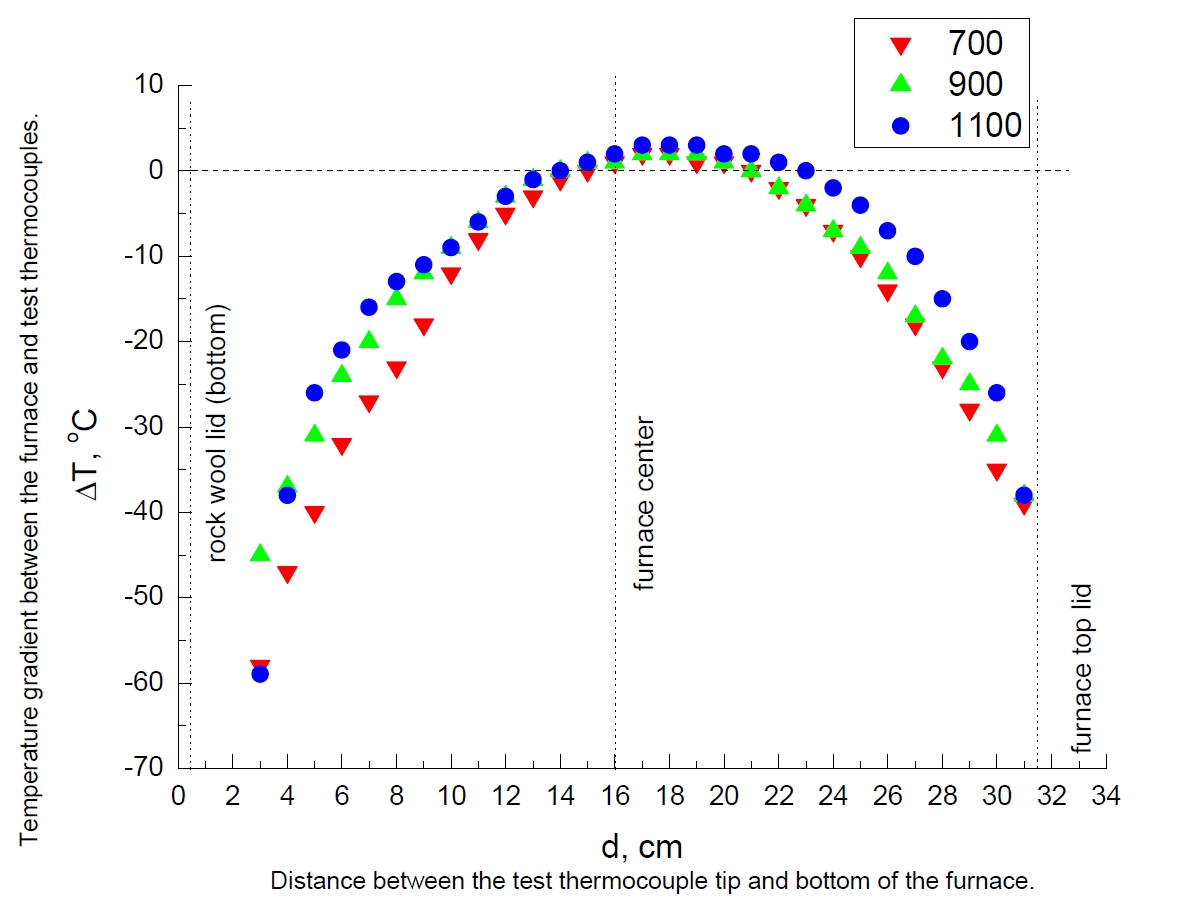

Temperature is not as simple thing as one would assume. The higher the temperature is, the more violent things occur. Heat is conducted on parts, heat is radiated from one place to another, and heat is convected with the gases. This mean there is no uniform temperature inside the furnace or inside the sample holder. Instead there are changing forces and if the conditions do not change, there may be some equilibrium. Temperature can be measured with the thermocouple of the furnace itself, but also with thermocouples inside the sample holder. In most cases they will not indicate the same temperature for simple reason; the thermocouples are not experiencing the same temperature. This is not a problem, but may be confusing for people who have not dealt with high temperature furnaces before. The chamber inside a furnace has a gradient of temperature. Some furnaces have less, some have more. Here is an example of a typical gradient.

When the furnace chamber has a sample holder in it, things change a bit. Reading temperature from a thermocouple inside a sample holder, the result will depend on the sample holder location in the furnace but also on many other things. If the furnace controller is guided by a thermocouple that is located inside the sample holder, there are important aspects to consider:

|